OS Giken Frequently Asked Questions

Q: What is a differential and what does it do?

The differential allows for wheel speed differences in a turn allowing the vehicle to be “free” when turning. The differential also acts as the last point between the engine and the driven wheels when power is transmitted. There are several types of limited slip differentials (LSD): Open, Viscous, Torsen, Clutch-type, etc. The OS Giken Super Lock LSD is our unique and patented style of clutch-type LSD which offers many advantages compared to its competitors.

Q: How does a clutch work?

In an automotive application, a clutch is necessary to connect the engine to the drivetrain and transmit energy to drive the wheels. Friction is necessary to connect the engine to the drivetrain. The higher the output of the engine, the more friction is needed to hold that amount of power.

OS Giken clutch kits are unique in that they are engineered with racing in mind to improve on the existing design in the vehicle. This is the reason that all OS Giken clutch kits include both the clutch disk(s) and flywheel. They are designed and sold as a unit to upgrade the entire system instead of working within the constraints of the OEM design. This eliminates any discrepancy in tolerances by combining parts from different manufacturers.

Q: What makes the OS Giken Super Lock LSD a desirable choice over the competition?

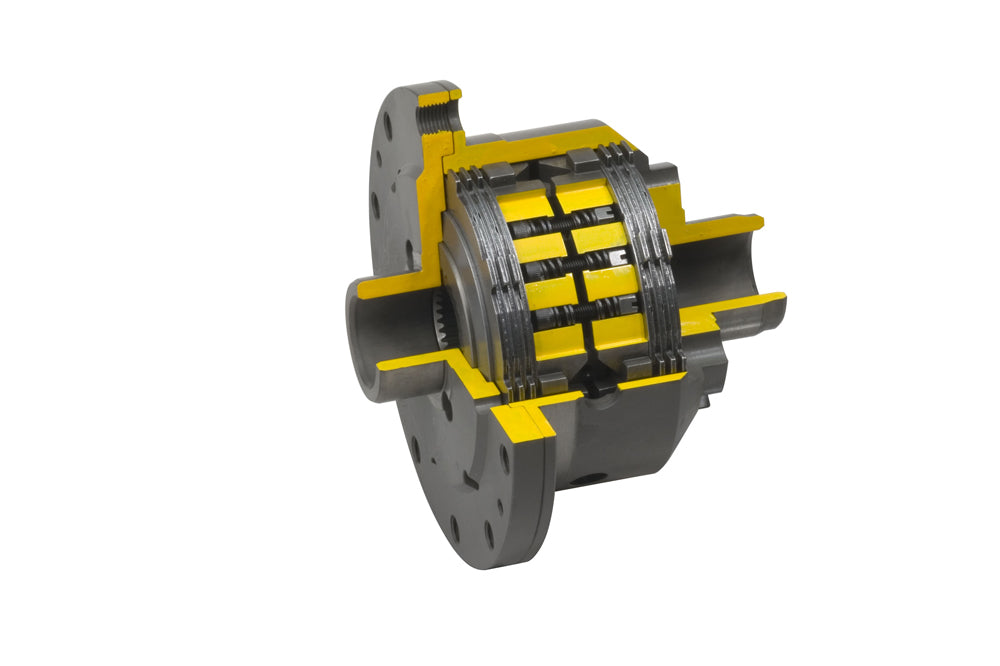

Under racing conditions, the function of the LSD is to allow the drive wheels to apply equal traction under acceleration and deceleration. Our OS Giken Super Lock LSD is engineered to be extremely responsive to throttle input to give the driver full control over differential action. Our units are a negative preload design which allows for minimal lock when power is not delivered (turn in) and progressive maximum lock 100% on corner exit. Our unit is capable of controlling when 100% lock happens dependant on estimated power delivery and grip available (tires).

Through its innovative and patented design, up to twice as many friction plates are able to fit into the housing when compared to our competitors' products. This enables the OS Giken Super Lock LSD to achieve true 100% locking capability. Our LSD is also customizable by adjusting the spring inside the pressure ring to achieve progressive lock and allow high powered vehicles controllable lockup. Additionally, its superior design allows for excellent smoothness in regards to lock, virtually eliminating the “chatter” associated with other clutch type LSD brands.

Each component of every OS Giken Super Lock LSD uses only the highest grade materials and manufacturing processes. They are constructed and finished to extremely tight tolerances to eliminate “break-in” period prior to racing conditions. Expect longer life out of LSD performance compared to its competition. Rebuilds are rarely needed and is recommended to have fluids changed periodically to prolong the life of the unit.

Q: What makes the OS Giken Racing Clutch lineup desirable compared to its competition?

Throughout the years of development and since its first introduction to the public in 1983, OS Giken clutches have always focused on extraordinary durability, drivability, and effective power transmission.

In order to properly develop a clutch system to maximize drivetrain performance, OS Giken determined that it would be most effective to engineer and manufacture clutch kits as a clutch/flywheel package. By doing this, OS has control over clutch tolerance specifications resulting in perfectly matched assemblies for every application.

Durability, drivability, and longevity is improved through the use of our full face metallic clutch discs and heat treated clutch components. Our full face design allows for more surface area for grip. This allows for much lower spring pressure (softer pedal) from the diaphragm spring in order to achieve a certain amount of torque capacity. Our patented pressure plates utilized a very smooth and gradual taper to them allowing for ease of clutch engagement.

Q: Why do all OS Giken Race Clutches make a ringing noise when disengaged?

All OS clutch kits utilize a free-floating pressure plate design. When the clutch pedal is depressed, the clutch plates float within the clutch housing and emit the ringing noise most will hear.

Traditional clutch designs secure the pressure plate to the cover through the use of a pressure plate drive strap (aka “granny strap”). The advantage of having the granny strap is that clutch operation remains noiseless whether the clutch is engaged or disengaged. However, in many situations where the clutch is being abused (i.e. “spirited” driving and/or racing), the granny strap can become a weak point in the system and has a tendency to bend or break.

With the OS free-floating pressure plate design, pressure applied to the disks is even throughout the clutch lifespan, and the friction material of the metallic disks is bonded through a specialized process (not riveted). This aids in increasing durability and lengthening the useful service life of our clutches. Power will continue to be transmitted effectively until the disks are extremely thin. Some race teams have gone through multiple seasons on an OS clutch before requiring a rebuild.